(Part 10, Environmental Hygiene, VPE)

Topic: Solid and liquid waste management of Farms. Sanitation and Disinfection of farm and hospital environment in Veterinary public practice for infection control.

Farm Waste Management | Sanitation and Disinfection of Farm

Disposal of Farm Waste

A proper system for the hygienic disposal of animal excreta is essential for the preservation of animal health and as an aid to the control of disease.

The disposal of excreta, together with the straw or other material used for bedding is complicated by the fact that this material has a considerable manurial value and usually has to be conserved or stored in some way until it can be conveniently applied to the land.

Collection and storage of animal manure

- Collection of dung and bedding from stable or cow shed.

- Storage of solid manure so that its potentially disease bearing state is rendered innocuous whilst at the same time its land fertilizing capacity is conserved.

- Conveyance of voided urine to an outside drainage system.

- Disposal or conservation of liquid manure.

Removal of Manure from Buildings

- The collection of solid manure in animal habitations under ordinary management is usually carried out once or twice daily.

- Removal from the building is usually effected either by means of a wheelbarrow or similar vehicle or often by simply throwing the manure through an open door on to a dump situated immediately outside the buildings.

- From the hygienic point of view a serious objection to this latter method is the close proximity of the dung heap to the buildings.

- While transporting these materials should not scattered or spilt and give rise to unnecessary filth on the yards and roadways where a barrow has to be used ,it should be made of metal and have widely slopping sides so that is easily retains the manure placed in it being of metal it can be washed and disinfected periodically.

- If number of animals kept are large means. It can be transported either by bullock cart or tractor.

Manure pit

- Should be for away from the stable or cowsheds, not only as a safeguard against smell, but also as a preventive measure against the nuisance of flies. Fresh manure forms an ideal breeding ground for the common house fly, a pest which may easily become a hindrance to clean milk production. Flies also cause considerable annoyance to the cows in summer, and there is some evidence that they may be a factor in the spread of mastitis.

- The common practice of depositing the manure in a dump immediately outside the buildings and into which the drainage system empties is most objectionable. A concrete pathway should connect the building and manure pit and where it is possible accessibility to the latter from a hard road is an advantage when it comes to transferring the manure to the land.

- The space required for a manure pit depends on number of factors. These include the number and species of animals kept the nature of the food consumed, the amount of bedding supplied and the extent to which it is re-used or discarded and the length of time the manure is to be stored. The manure pits have a capacity of not more than 1 cubic metre unless it be emptied every 48 hrs. It is suggested that a manure pit should be of such a size as to ensure that it must be emptied every 6 to 8 weeks.

- If bedding is used it should be separated from manure and can be dried for further use

- Approximate quantity of dung expelled per animal per day. Horse - 10-12 Kg, Ox - 30-35 Kg, Sheep - 1-3 kg, Swine - 1.5-3kg.

- The capacity manure pit for 100 cattle per day is 6.4 sq metres. The retaining walls about 1.2-1.5 metres high preferably of brick or concrete. Bottom should always be impervious, cement concrete is the best material, there should be a fall to one end where a drain leads to the liquid manure tank.

- The manure pit should be roofed over with galvanized iron or other suitable material to prevent the leeching of the valuable soluble constituents, nitrogen, phosphates and potash from the manure.

- The roof must allow free circulation of air over the manure, otherwise the latter may get too hot and so deteriorate.

- To make the stored manure to become fertilizer anaerobic condition is essential hence the manure mass is tightly packed.

- These conditions essential for the making of good manure also serve to prevent the multiplication of flies and to bring about the destruction of certain pathogenic bacteria and strongyle and other worm larvae.

- In certain circumstances manure may be directly applied to the land without storage, but it is to be spread on arable land or on field not being used for livestock since it may remain potentially infective with the organisms of tuberculosis paratuberculosis and with parasitic ova and larva for considerable period.

Liquid manure

- The urine and other organic liquid waste should be drained with surface channels and collected in liquid manure tank.

- The advantage of surface channel are not blocked, and economy to construct.

Liquid manure Tank

- The channels from the animal houses still converge at the inspection chamber.

- From this chamber one pipe carried the liquid to the settling chamber.

- The settling chamber is constructed of cement concrete throughout or with cement concrete floor and walls of brick faced with cement. From the settling chamber liquid alone carried to liquid manure pit and liquid is pumped out.

- The tank must be made of impervious material throughout and the bottom should be constricted of reinforced concrete.

- The sides may also be build of reinforced concrete or alternatively be brick built and faced inside with a good coating of cement Absolute gas tightness in a liquid manure tank is essential in order to conserve the ammonia.

Sanitation of Animals Houses

The dictionary meaning of the word sanitation is the science of safeguarding health.

According to the World Health Organization environmental sanitation embraces the

control of all those factors in man‟s (in our context animals) physical environment

which exercise a deleterious effect on the physical development ( to productivity), health

and survival. The physical environment encompasses the non-living objects and

physical factors affecting the animals, viz., air, ventilation, lighting, noise , climate and

water. In fact the term sanitation covers the whole field of controlling the environment

of animals with a view to prevent disease and promote health.

The basic problems encountered during the maintenance of sanitation in animal houses

included the lack of awareness and ignorance of nearly 80% of our population about the

role of environmental sanitation in the protection and promotion of their own health

and safety and in the alleviation of their poverty.

Water requirements for animals/animal houses

Dairy cows and buffaloes under average feeding conditions require about 28 litres of

water per day for maintenance purpose and additional 3 litres of water for each litre of

milk produced. In addition, for washing and cleansing of cow-sheds, the animal

themselves, utensils, etc., an average of another 45-70 litres of water per cow is

necessary. Thus, for all purposes, a daily supply of 110 litres of water per cow is

necessary.

A horse under average stable-feeding conditions will drink about 36 litres of water per

day. For washing and other general stable purposes, an additional 36 litres of water is

required. An average daily allowance of 18 litres of waste per head would be sufficient

for sheep and goats. For pigs, about 40 litres of water may be provided per day head for

all purposes. On an average 100 hens require 20-30 litres of water per day.

Objectives of sanitation

The aim of ensuring sanitation within animal houses are

(i) to establish hygienic

atmosphere and structures and

(ii) to create conditions for comfortable living of the

livestock (including poultry and ducks) so that they may remain healthy and productive.

Requirements of Livestock Buildings

- This aspect is of prime importance in maintaining good sanitation. Farm livestock are hometherms. They maintain a thermal balance between the heat they produce or gain from the environment and the heat they loose to it.

- The heat produced and released by the body is related to the working efficiency and production. While small amount of heat is lost with excretions and secretions, the main losses are through radiation, convection, conduction and evaporation.

- The temperature of surroundings, air temperature and humidity of air inside the sheds and movement of air within and outside the buildings determine the heat loss/ gain by convection.

- Temperature regulation of the body is a function of immense importance especially during hot and cold weather to maintain good health and productivity. Similarly, the atmosphere with 30 to 90 per cent relative humidity allows the livestock to thrive well. The moisture produced by the animals within the sheds has to be removed through proper ventilation.

- Air movement inside the animal house requires due attention to ensure health and productivity of livestock. Air temperature above and below body temperature tend to reduce dissemination of body temperature and compels animals through more exercise, more feed intake and sufferings.

- The animals should be kept in thermo comfort zone, within which they capable of giving an optimal performance. They should not be forced to huddle or separate themselves warm or cool, respectively. They should remain in complete harmony with their environment. Development of such a zone depends on many factors, viz., species , age, weight and sex of animals and feeding rate, acclimatization, husbandry system.

Drainage of Buildings

- To maintain sanitation in animal house one has to pay attention in drainage. The drainage system may conveniently be divided into three sections which all inter connected. That part inside and outside the building situated above ground level and leading to.

- The underground drain pipes and fittings in turn or connected to,

- The public sewer cesspool, septic tank or other means of disposal.

- The general principles of only drainage system

- The pipes should be made of non absorbent material and be laid with air and water tight joints.

- The drains should be laid in straight lines between points of access all changes of direction or gradient being open to inspection. All connections being on made that the incoming drain points in the direction of the flow of sewage.

- The drain should be laid to gradients which will ensure their being self cleaning.

- All inlets to fowl drain should be trapped.

- No drain should pass under buildings.

- All entrance to drains should be outside the building.

- There should be ample means of access for inspection.

- The drainage should be disconnected from the sewer or other outfall by means of a proper intercepting trap.

- The drainage system should be properly ventilated.

- It is desirable to provide a separate system of drains to take the rainwater in most cases.

Drain pipes

Pipes for underground drains must possess strength to withstand the pressure of the

super imposed soil and the weight and jar of traffic. Strength is also necessary to resist

the internal pressure of gases. Drain pipes must have a smooth internal face so that the

free passage of waste matter is not hindered. The internal surface must also resist the

corrosion of liquids or gases.

Pipes must be durable be able to withstand alternating temperatures, the action of

chemicals and the friction of sand and other solid particles. Absolute impermeability to

gases and water is an essential feature without which any drain pipe is not only useless

but extremely dangerous as otherwise the surrounding soil would soon become the

stoneware or fireclay pipes when well laid are always cleaner than iron drains and will in

ordinary circumstances remain practically tight for long periods. On the other hand iron

pipes will remain perfectly tight for long periods but do not remain for any length of

time perfectly clean. Because of greater length of iron pipes fewer joints are required

than with stoneware fireclay pipes.

Bends

The drainage pipes must be laid in straight line if abrupt deviations from the straight are

necessary bend are used. At the curve chokage is liable to occur the curved pipes are

frequently provided with removable bolted covers.

Junctions

Junctions at right angles are to be avoided for free flow. Junction should have

inspection chambers and it is covered by lid which is securely bolted down. The

optimum size of the pipe for livestock farm is 10-15 cm internal diameter.

Trap

Is to prevent the gas escaping from the sewer to the house.

Syphone trap

- The reliability of a trap depends primarily upon the depth to which the in-bent portion of the piping. An ideal trap effectively prevent sewer gases under ordinary circumstances from passing up the inlet pipes. It must be self cleansing.

Dip stone, mason‟s or built trap

- It is a receptacle built of brick. It is of the worst forms of traps. It is not self cleaning, allow to settle solids.

Buchan‟s Intercepting Syphon trap

- It is provided with an abrupt inlet and a gradual outlet, and the seal in this trap is very effective

Gully trap

- In the drainage system the fluid alone pass into the drain and at the same time hold back the more solid portion. For this purpose gully traps are placed at the inlet of the drains, they are designed to catch and retain any solid matter.

Laying of a Drainage System

When laying drain pipes and fittings in a drench care must be exercised to see that the

trench has a firm bottom. If the soil is of a loose character it is well to make a solid bed

of concrete for the pipes.

The gradient of its pipes should be such as to ensure a steady and even passage of

sewage. For ordinary drains from most animal habitations a speed of 10 cm/second is

satisfactory and this attained in a 10 cm pipe if there is a gradient of one in forty and in

a 15 cm pipe with a gradient of one in sixty is maintained .

All joints must be made perfectly gas and water- proof and the material used for sealing

the join must be able to resist the action of fluids from without and of fluids and gases

from within. One part of cement and one part of sand makes a excellent jointing

material for stoneware or fireclay pipes.

Defects

- Defects in drains may be due to several cause

- Blockage of the pipes or fittings through the entrance of solid objects.

- In sufficient gradient or conversely to steep a gradient.

- Imperfect laying of traps so that these become tilted out of line so reducing the depth of the seal.

- Bad workman-ship in laying drains.

- Using pipes which are too large or two small.

- Too many bends in a system.

Testing of drains

Drains must be tested after laying to ensure that they are gas and water tight and that

the water seals of the traps are satisfactory. Tests are carried out on the various sections

of a drainage system during its construction and a final test on the whole system when

completed. Thereafter periodical tests should be made from time to time to ascertain

that the system remains satisfactory as defects may developed from various causes

which if not rectified may cause serious pollution.

The methods of testing drains are described below

- The air and smoke tests: The air test consists of plugging the open ends of the drains and ventilating pipes and the pumping in air under a pressure sufficient to be indicated on a pressure gauge. If the gauge does not show that a fixed pressure is being mentioned this denotes a leak or leakage. These can generally be located by filling the pipes with dense white smoke afterwards plugging the pipes and applying the same pressure before. This will force the smoke out at the defective parts and enable them to be located and made good. This test should be continued until the gauge remains steady and proves that the drains are sound.

- Hydraulic test: In the hydraulic test the outlet of a drain or a section of it is plugged with a extending rubber bag or other patent stopper, and the section to be tested then filled with water . The water is left in for two or three hours and if a leak exists its pressure will be indicated by a fall in the head of water at the point of observation.

Disinfection of Animals Houses

Introduction

The term disinfectant is applied to agents which kills or prevent multiplication of

microorganisms, particularly those which cause disease i.e. bacteria, protozoa, fungi or

viruses, Disinfectants are usually applied to in animate surfaces

Since few disinfectants act instantly, ample time must be allows for their bactericidal

effect. As bacterial agents, most disinfectants seem to act more effectively when applied

in solution then as an emulsion powder, aerosol or gas because solutions penetrate to a

greater depth.

Germicidal activity of disinfectant solutions is greater when they are heated because hot

solutions penetrate manure and other organic debris better than cold. It is extremely

important to remove as much organic matter as practicable from the areas to be

disinfected.

The disinfectant should be applied as spray with sufficient force to drive the solution

into all cracks and services.

Properties of a Disinfectant

The ideal properties of a disinfectant are

- It should be rapidly effective.

- It should have a broad spectrum of activity excluding bacteria, viruses and fungi.

- It should not allow emergence of resistant populations.

- It should not be inactivated by protein.

- It should be minimally toxic.

- It should be non straining and un corrosive.

- It should not has the skin by direct action or sensitization.

- It should be adourless and decodorsing.

- It should possess residual action after rienseing.

- It should have detergent properties and it should be simple and economics to use.

Types of Disinfectant

There are two types of disinfectants

- Physical agents

- Chemical agents

Physical Agents

Two important physical agents or heat and light

Heat

- Heat sterilization is an efficient and convenient procedure. Moist heat has the advantage of penetrating climps of organic matter and reaches surfaces not readily available to chemical disinfectants.

- Dry heat requires higher temperatures and larger exposure periods than moist hat. Moist heat produces its germicidal effect by protein Coagulation, whereas dry heat oxidizes or -------------- microorganisms.

Light

- Ultraviolet light has antimicrobial activity. Ultraviolet wavelength of 254-280 nm are most effective against gram negative and non sporulating bacteria, while stephylocci and streptococci as well as viruses are resistant.

Chemical Agents

Chemical agents may be classified as follows

- Oxidising agents

- Reducing agents

- Acids and alkalis

- Alcohol

- Phenol and cresols

- Dyes

- Detergents and surface active agents

- Miscellaneous organic compounds

Oxidising agents

Oxidising agents are rapid in action, and can be divided into those which release oxygen

oxidation without the release of oxygen the halogens.

Peroxides

Hydrogen peroxide solution - An aqueous solution of hydrogen peroxide is colourless and adourless but has a

characteristic taste. Hydrogen peroxide is relatively stable when slightly acidified

but decomposes is alkaline media and in contact with organic matter and metals.

Hydrogen peroxide is a deodorant by virtue of the strong oxidizing effect of the

nascent oxygen produced in contact with organic tissue. The second action is

mechanical cleansing action resulting from the rapid release of oxygen

Potassium permanganate

Consists of dark, adourless, purble crystals with a metabolic luster, which are solubless water giving pink to deep purple solutions depending on concentrations. Solutions of

potassium permanganate have strong oxidizing properties without releasing gaseous

oxygen.

Halogens

Sodium Hypochlorite- contains approximately 0.5% W/V of available chlorine.

Reducing agents

Formaldehyde useful to disinfect straw, clotheing, hay etc a 2% formaldehyde in used as

spray.

Sulphur dioxide

Sulphur dioxide is liberated as a gas when sulphur is ingnited. It is used as fumignant

disinfectant for animal houses to destroy bacteria and viruses, parasites and vermin. for

every 3m3 of our 0.5 kg of sulphur should be burned. The disadvantage is it attack and

corrodes metal, -------- fabries and blackes dyes.

Acids and Alkalis

The strong mineral acids can be used as disinfectants but their corrosive actions limit

their usefulness to disinfection of -------- surfaces.

Several alkalis are in common use as disinfectant, e.g sodium hydroxide, sodium

carbonate and quick lime. Most bacteria are inactivated above pH 9, but a particular

property of the alkalis is their antiviral activity. A 4% solution of sodium carbonate

(washing soda) is employed in the cleansing and disinfection procedures required after

or outbreak of fat and mouth disease.

Acid alcohol is effective in inactivating bacterial spares.

Phenol and Cresols

Phenols and cresols and their derivatives such as the various chlorinated cresols and

phenyl mercuric compounds are used.

Phenol is toxic but it is a good disinfectant even at low concentration (0.5%)

Cresol is straw coloured liquid which darkens with age and exposure, less soluble in

water but soluble in organic solvents. Cresol in very effective against acid fast bacteria

but less effective against viruses and it has no effect on spores. It act even in the

presence of organic matter. Solution of cresol and soap (Lysol) is preferred because of

its greater solubility in water. Phenol should not be used in ------ since it ----- mick and

mink products. Phenol and cresol are toxic to cats and dogs.

Cholroxyloenol: Is a white or creamy white crystalline substance with a slight phenolic

adour. It is insoluble in water but soluble in organic solvents and soap solutions . It is

bactericide mainly against gram positive bacteria.

Recycling of Farm Wastes

The farm waste may be solid, semisolid or liquid. Some waste may be treated primarily

as sewage and the residues emanating from the digestion tank serve as manure. The

sludge from the primary sedimentation tank could be disposed by land bury or by

composting while the liquid effluent after the separation of activated sludge in the

secondary sedimentation tank is disposed to courses. Besides, the sludge may also be

disposed in the sea as done in Mumbai, spread over the land or used as manure.

The effluent from secondary settling tank, ie disposed into water courses such as rivers

and streams should be diluted at least 8:1 (water: effluent) in manner that it should not

contain > 10 ppm of suspended solids and 10ppm of BOD. Since people may use as

source waters, the effluents needs essentially to be rendered pathogen free by

chlorination. If chemicals are not removed from the water it could prove toxic to man,

fish, agriculture and limits its use for other purpose.

Oxidation pond

It is a cheap method of sewage treatment. It is an open shallow pool 1 to 1.5m deep with

an inlet and outlet. It functions in the presence of algae, certain types of bacteria and

sunlight. The organic matter is oxidized by bacteria to CO2 , ammonia and water.

The algae with the help of sunlight utilizes CO2 , water and inorganic minerals for their

growth and liberates oxygen which together with atmospheric oxygen induces the

process of oxidation in the pond. It can become profitable of sewage purification for a

small community. Twenty two acres of land is required to develop an oxidation pond.

Oxidation ditches

With the use of mechanical rotors for extended aeration, the aerated lagoons can also be

used for purification of sewage and wastes generated by townships with 5000 to 20000

population. Only one acre of land is required for an oxidation ditch and 2.5 acres for

aerated lagoon.

Collection of wastes

Dung, feed wastes, soiled bedding , etc. forming solid wastes and waste water

constituting liquid manure can be collected separately or flushed out together with

plenty of water through hose pipes. The former group of wastes are lifted into wheel

barrows or trolleys and drawn out by bullock carts.

Solid manure is to be collected and removed from the shed at least twice daily and

should be stored in manure pit with impervious walls which is located at a minimum

distance of 10m from a well, river, tank or boundary of an adjoining land property to

safeguard against the menace of foul odours and flies.

Types of Manure and Solid Waste

The production of manure is on an average 40 kg per day per one adult unit ( one adult

cattle or buffalo above 3 years of age). One calf blow one year or one adult sheep or goat

or pig produces manure roughly equal to 1/3rd of an adult unit.

Aggregates of small globules are voided by sheep and goats, which are quite hard and

can be swept of floors. For pig paddock, 0.5 m wide trench covered with slats or iron

grills can be provided along the outer border where the animals will void the faeces

which will drop through the grill to fall at the bottom of the trench, from where it can be

collected periodically.

Manure pit

Simple manure pit for villages can be constructed by digging out on an elevated land

4x3 sqm pit of 2 m depth with a roof constructed of locally available material. The

objective is to desiccate the manure quickly to dung cake, and to prevent entry of rain

water into the pit to overcome leaching of plant nutrients.

Another way is to construct a brick walled pit with cement concrete bottom. There

should be fall of base to one end from where a drain is to lead to the liquid manure

chamber. This pit as usual would have roof at a height of permitting free circulation of

air over the manure yet preventing leaching of valuable soluble plant nutrients. It also

prevents anaerobic conditions causing deterioration of manure.

The manure is well turned periodically to ensure uniform decomposition of fresh

manure that is added to the pit daily. It is essential for destruction of eggs and larvae of

parasites which are normally present in the dung of animals.

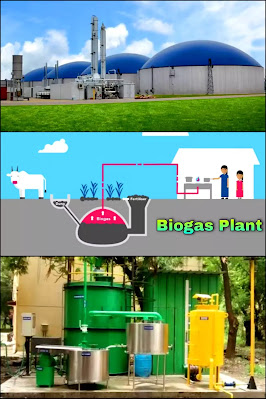

Biogas plant

At village or farm level, the disposal of farmyard manure can be utilized for production

biogas, fertilizer or compost. The Ministry of Non-Conventional Energy Resources,

Govt. of India, is implementing biogas program, - gas being produced from cattle dung,

other organic wastes and / or human excreta in a system popularly known as Gobar-gas

plant through the process of digestion. The plant consist of

- Mixing tank and inlet

- Digester

- Gas holder or storage dome

The slurry from the biogas plant is a good quality manure free from weeds, sedds, foul

smell and pathogens.

Liquid manure

When the slurry from the biogas plant is used in liquid form as it comes out, it can be

easily distributed in the field by linking the outlets with the main irrigation channel or

through an appropriate handling system.

Composting

Rectangular pits of 3x2x1.5 m are dug. A layer of straw, animal bedding, garbage and

leaves is first put in the pit. Digested slurry is then allowed to flow into the pit. Alternate

layers of refuse and slurry are laid until the pit is full. Bamboo poles having holes 10cm

apart are placed in the compostable material for aeration. Finally the pit is plastered

with mud layer. This will minimize the loss of nitrogen from the pit. After one pit is

filled, the same process is repeated for filling another pits because compost from such

pits is usable as manure only after 3 to 4 months. Composting process consist of

compost heaps, semi-dried slurry and slurry filter bed.

Previous VPE notes of Environmental Hygiene are Environment & Ecosystem, Biodiversity, Natural Resources, Pollution, Water sources, contamination and Evaluation, Water Purification & Sewage Disposal, Disaster Management, Biomedical Waste Management etc. Hope the note will benefited you. You can contact us by using Contact form for pdf file of this note. For any query knock us. Stay tuned. Thank You. Happy Learning!